Current location:Home > 4 hydraulic cylinder seal kit >

4 hydraulic cylinder seal kit

2025-08-15 19:45

2025-08-15 19:38

In industries like automotive, aerospace, and manufacturing, where precision and reliability are crucial, the quality of oil seals cannot be overstated. In automotive engines, for example, oil seals ensure that engine oil stays within the system, lubricating moving parts and preventing costly damage. In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations

In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations industrial oil seals.

industrial oil seals.

In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations

In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations In the aerospace industry, they are vital for maintaining the integrity of hydraulic systems, ensuring safe flight operations industrial oil seals.

industrial oil seals.

...

2025-08-15 19:26

2025-08-15 18:55

2025-08-15 18:46

2025-08-15 18:19

Another key feature of combi oil seals is their ease of installation and replacement

. These seals are designed to be easy to install and remove, making maintenance and repairs quick and convenient. This helps to minimize downtime and reduce overall maintenance costs for the machinery....

2025-08-15 18:03

Single lip oil seals are commonly used in a wide range of machinery and automotive applications single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.

single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.

single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.

single lip oil seal. They can be found in engines, gearboxes, pumps, and other types of equipment that require a reliable sealing solution to prevent oil leakage. These seals are available in various sizes and materials to suit different operating conditions and environments.

...

2025-08-15 17:36

2025-08-15 17:32

2025-08-15 17:25

Latest articles

The material selection for hydraulic shaft seals is crucial, as it directly impacts the seal's durability and effectiveness. Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear

Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear Materials like rubber, polyurethane, and PTFE (Teflon) are commonly used due to their resistance to chemicals, temperature fluctuations, and wear hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.

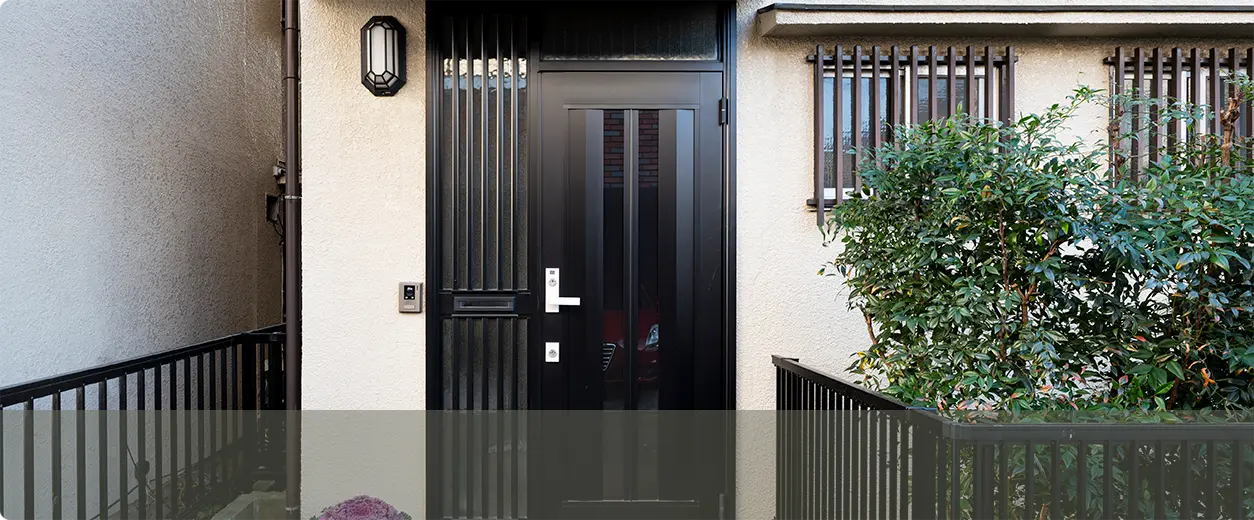

hydraulic shaft seal. The choice of material depends on factors such as the type of fluid, operating pressure, and speed of the shaft.Manufactured from high-quality materials like stainless steel or durable polymers, these rollers offer resistance against corrosion, rust, and weathering heavy sliding door rollers. Many models feature adjustable designs, allowing for fine-tuning of the door's balance and alignment, ensuring a seamless glide even as the door ages or undergoes minor structural changes.

heavy sliding door rollers. Many models feature adjustable designs, allowing for fine-tuning of the door's balance and alignment, ensuring a seamless glide even as the door ages or undergoes minor structural changes.

heavy sliding door rollers. Many models feature adjustable designs, allowing for fine-tuning of the door's balance and alignment, ensuring a seamless glide even as the door ages or undergoes minor structural changes.

heavy sliding door rollers. Many models feature adjustable designs, allowing for fine-tuning of the door's balance and alignment, ensuring a seamless glide even as the door ages or undergoes minor structural changes.